Troubleshooting Kaeser compressors requires a systematic approach to identify and resolve issues efficiently. This guide provides insights into common problems, solutions, and maintenance tips to ensure optimal performance and reliability.

Importance of Regular Maintenance

Regular maintenance is crucial for ensuring the reliability and efficiency of Kaeser compressors. It helps prevent unexpected shutdowns, reduces repair costs, and extends the lifespan of the equipment. By addressing issues like oil level checks, filter cleaning, and part replacements, maintenance ensures optimal performance. Ignoring routine upkeep can lead to severe operational problems, making scheduled maintenance a vital practice for sustained productivity and safety.

Common Issues and Their Solutions

Kaeser compressors often face issues like air pressure drops, motor overheating, and faulty wiring. These can be resolved by cleaning air filters, ensuring proper ventilation, and inspecting electrical connections. Addressing these problems promptly prevents downtime and maintains efficiency. Regular checks and timely repairs are essential for prolonging the compressor’s lifespan and ensuring smooth operation.

Understanding Kaeser Compressor Operation

Kaeser compressors convert power into potential energy through compressing air, utilizing components like motors, air filters, and valves to ensure efficient and reliable compressed air supply.

Basics of Compressor Function

Kaeser compressors convert power into potential energy by compressing air, reducing its volume, and increasing pressure. The process involves drawing in ambient air through an inlet, compressing it via rotating screws or pistons, and storing it in a receiver tank for use. This fundamental operation ensures a reliable and consistent compressed air supply, essential for various industrial applications.

Components Overview

Kaeser compressors consist of key components like the screw compressor block, motor, oil separator, and control system. The screw compressor block generates compressed air, while the motor provides power. The oil separator ensures efficient lubrication and cooling. Control systems monitor operation and maintain performance. Regular maintenance of these components is crucial for optimal functionality and service life.

Common Problems and Fault Codes

Kaeser compressors may face issues like wiring problems, motor faults, and sensor malfunctions. Fault codes help identify specific problems, enabling quick diagnosis and effective solutions.

Overview of Typical Issues

Common issues with Kaeser compressors include reduced performance, motor overheating, and fault code displays. These problems often stem from wiring issues, worn components, or environmental factors. Addressing these promptly prevents further damage and ensures efficiency. Regular maintenance and understanding fault codes are key to resolving these issues effectively and maintaining optimal compressor operation.

Interpreting Fault Codes

Fault codes on Kaeser compressors indicate specific system issues, such as motor faults or sensor malfunctions. Each code corresponds to a detailed explanation in the service manual, guiding technicians to the root cause. Understanding these codes enables quick diagnosis and repair, minimizing downtime and ensuring efficient operation. Regular code checks are crucial for proactive maintenance and system reliability.

Diagnostic Procedures

Kaeser compressor diagnostics involve systematic checks of electrical, mechanical, and control systems. Initial assessments include verifying power supply, checking for fault codes, and inspecting components for wear or damage. Advanced techniques may require specialized tools and reference to the service manual for precise troubleshooting and effective issue resolution.

Initial Checks

Initial checks for Kaeser compressors involve verifying power supply, ensuring proper installation, and reviewing fault codes. Inspect air filters, oil levels, and belts for wear. Check for loose connections and blockages in intake or discharge lines. Refer to the service manual for specific procedures and guidelines to ensure safe and accurate troubleshooting. This step helps identify common issues quickly, preventing further complications.

Advanced Diagnostic Techniques

Advanced diagnostics for Kaeser compressors involve analyzing system performance using specialized tools. Utilize pressure gauges to check for pressure drops and flow restrictions. Perform thermal imaging to detect overheating components. Review historical fault codes and trends to identify recurring issues. Consult the service manual for detailed procedures and utilize manufacturer-specific software for in-depth analysis, ensuring precise identification and resolution of complex problems efficiently;

Solutions to Common Issues

Kaeser compressor issues often involve wiring, motor, or maintenance problems. Regularly check and replace air filters, inspect wiring connections, and ensure proper motor cooling. Addressing these common faults promptly enhances efficiency and longevity, minimizing downtime and operational costs effectively.

Fixing Wiring Problems

Wiring issues in Kaeser compressors can disrupt operation. Check for loose connections, damaged cables, and incorrect voltage supply. Ensure all wires match the compressor’s specifications. Regularly inspect circuit breakers and fuses. Repair or replace faulty components promptly to prevent further damage. Always refer to the service manual for accurate wiring diagrams and procedures to ensure safety and proper functionality of the compressor system.

Resolving Motor Issues

Motor problems in Kaeser compressors often stem from overheating or power supply issues. Check for blocked air vents, worn bearings, or malfunctioning thermal overload protectors. Ensure proper voltage supply and inspect for loose connections. Regular lubrication and timely replacement of worn parts can prevent motor failure. Always consult the service manual for detailed diagnostic steps and follow safety guidelines to address motor issues effectively and safely.

Maintenance and Service

Regular maintenance ensures optimal performance. It includes scheduled service tasks, oil changes, and parts replacement. Refer to the service manual for detailed procedures and guidelines.

Scheduled Maintenance

Scheduled maintenance is crucial for Kaeser compressors. Regular tasks include oil changes, filter replacements, and checking drive belts. Adhering to the maintenance schedule ensures reliability and prevents downtime. Always use original parts and follow guidelines in the service manual. Proper documentation of maintenance helps track equipment health and ensures compliance with manufacturer recommendations.

Parts Replacement

Replacing parts on Kaeser compressors requires precision and authenticity. Always use original Kaeser components to ensure compatibility and performance. Replacing worn or damaged parts like piston rings, oil filters, and belts is essential. Follow the service manual for correct installation procedures. Proper parts replacement prevents further damage and maintains compressor efficiency, ensuring reliable operation and extending equipment lifespan effectively.

Safety and Environmental Considerations

Adhere to safety regulations and environmental guidelines when operating Kaeser compressors. Prevent oil spills, ensure proper disposal, and follow energy-efficient practices to minimize ecological impact.

Safe Operating Practices

Always follow safety guidelines when operating Kaeser compressors. Ensure the inlet air is free from hazardous gases and avoid contact with lubricants. Regularly check oil levels and ensure proper ventilation to prevent accidents. Never remove safety labels and keep the enclosure closed during operation. Proper emergency procedures should be in place to handle any unforeseen issues efficiently.

Environmental Protection

Protecting the environment is crucial when maintaining Kaeser compressors. Ensure cooling oil does not leak into water systems or soil. Dispose of used oil and filters according to local regulations. Regularly check for oil contamination and prevent it from entering drainage systems. Adhere to national environmental laws to minimize ecological impact during compressor operation and maintenance.

Tools and Resources

Essential tools like multimeters and pressure gauges are vital for diagnosing issues. Refer to the service manual and online guides for detailed troubleshooting procedures and support.

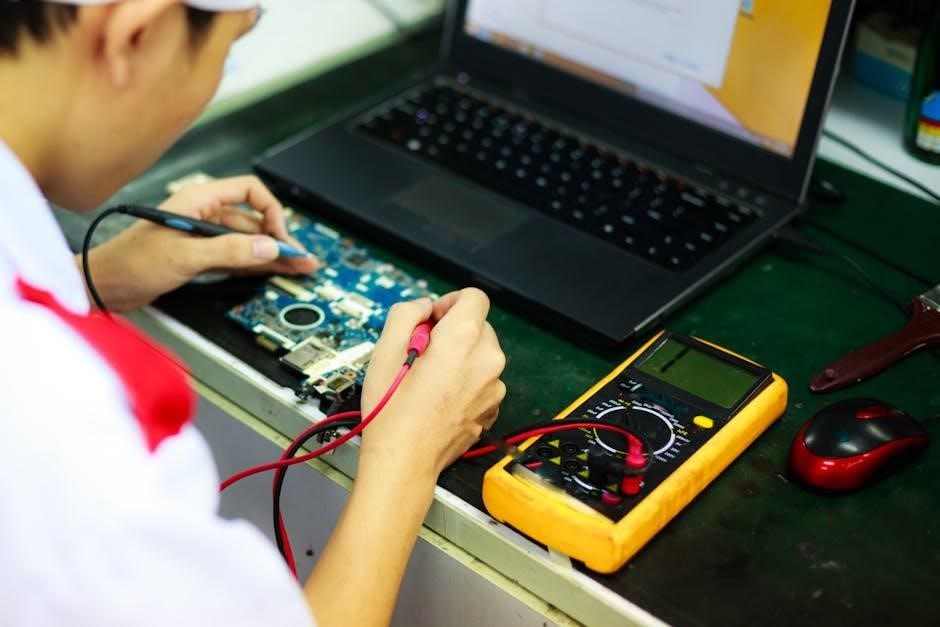

Essential Tools

Diagnosing Kaeser compressor issues requires specific tools. A multimeter helps check electrical circuits, while pressure gauges monitor air pressure. Additionally, thermal imaging cameras can detect overheating components. Proper wrenches and socket sets are necessary for mechanical repairs. Ensure all tools are calibrated and suitable for the compressor’s specifications to maintain safety and accuracy during troubleshooting and maintenance tasks.

Service Manual Reference

The Kaeser compressor service manual provides detailed instructions for troubleshooting, maintenance, and repair. It includes diagrams, technical specifications, and parts lists. Referencing the manual ensures compliance with manufacturer guidelines, helping technicians identify fault codes and perform routine checks. Regularly updated, it serves as a comprehensive resource for resolving issues efficiently and safely, covering both basic and advanced diagnostic procedures.

Troubleshooting Resources

Kaeser provides extensive troubleshooting resources, including online guides, manufacturer support, and detailed service manuals. These resources help users identify and resolve issues efficiently, ensuring optimal compressor performance.

Online Guides

Kaeser offers comprehensive online guides and PDF manuals that provide detailed troubleshooting steps, fault code interpretations, and maintenance tips. These resources are accessible on the official Kaeser website, ensuring users can quickly diagnose and resolve common compressor issues. Additionally, video tutorials and interactive tools are available to enhance understanding and application of troubleshooting techniques for optimal compressor performance and longevity.

Manufacturer Support

Kaeser provides dedicated manufacturer support, including certified technicians and extensive resources. Their training programs, developed with industry standards, ensure comprehensive troubleshooting guidance. Users can access service manuals, troubleshooting guides, and expert assistance directly from Kaeser, ensuring efficient resolution of compressor issues and maintaining system reliability and performance.

Best Practices

Adopting best practices ensures efficient Kaeser compressor operation and longevity. Regular maintenance, adherence to safety protocols, and timely issue resolution are key to optimal performance and reliability.

Preventive Measures

Implementing preventive measures is crucial for maintaining Kaeser compressors. Regular oil changes, filter cleaning, and belt inspections help prevent breakdowns. Monitoring operating conditions and adhering to maintenance schedules ensures reliability. Addressing minor issues early avoids costly repairs and downtime, promoting continuous efficiency and extending the compressor’s lifespan significantly. Consistent preventive care is essential for optimal performance and longevity.

Continuous Improvement

Continuous improvement is vital for enhancing Kaeser compressor efficiency. Regular training, updating to new technologies, and analyzing operational data drive progress. Incorporating feedback from maintenance and troubleshooting efforts helps refine processes. Staying informed about industry advancements ensures systems remain up-to-date, optimizing performance and reducing downtime. This proactive approach fosters a culture of ongoing enhancement, ensuring compressors operate at peak effectiveness and adapt to evolving demands.